Compression springs made of stainless and spring steel

All-round excellence:

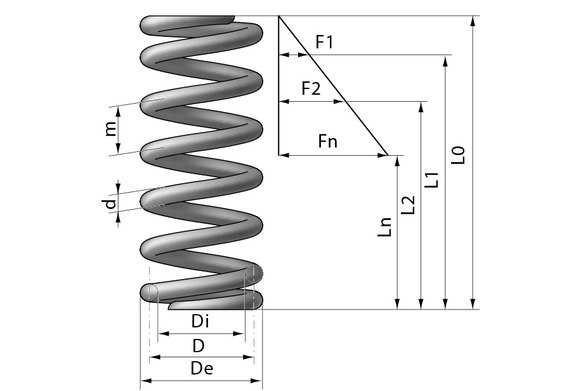

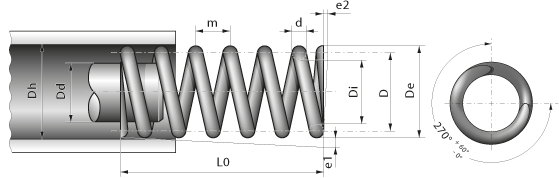

these cylindrical compression springs are manufactured from round wires with a constant diameter. The mean distance between the coils is constant along spring axis, whereby the left and right coils are created. The technical springs have a linear characteristic curve, stress is mainly applied to the spring axis.

The standard springs are manufactured in accordance with the quality regulations for cold-coiled compression springs (DIN 2095, degree 1). In addition to the dimensions according to DIN 2098, with our extreme Technology Spectrum, we offer a large selection of practically graduated interim sizes. The right-angled springs are created and ground with one coil each (d >= 0.5mm); they are made of stainless steel or patented spring steel. Compression springs made of spring steel are bonderised dark grey to black. You can also order additional protection against corrosion for springs made of spring steel if desired.

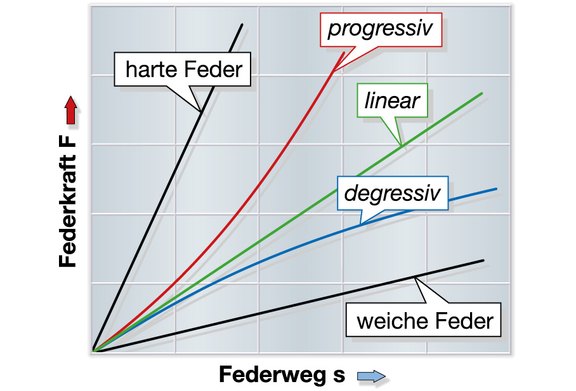

The properties can be assessed with the spring characteristic curve. It shows the force “F” depending on the spring deflection “s!. The spring rate defines the ratio of spring force to spring deflection – for cylindrical coil compression springs, the ratio is largely linear. Positive characteristic curves are generated by varying the wire/coil diameter or the coil spacing. In general, the following applies when calculating the compression springs:

d >: harder

D >: softer

n >: softer

The spring rate can also be influenced by the material – our technical service will be happy to advise you.

Settling and Relaxation

If the elasticity of the material is exceeded, the compression spring settles. This results in plastic deformation. After relief, the original length “Lo” is no longer reached – this results in a loss of force, which is known as relaxation. This leads to residual stress, which has a favourable effect on the further stressing of the spring. By means of a targeted pre-setting—i.e. stressing the spring on a block for a specific period—this is used to ensure that the spring can no longer settle later. Our standard compression springs are not pre-set – however, they are longer than Lo by the rate of settlement, this can be up to 5 % of the Lo.

Our tip for durability

Pre-set the springs or commission us to do so for a small surcharge. If you want durability, please talk to us because it depends on pre-set training, elasticity limits, stresses, other factors and dynamic influences, for example. Our standard springs are tuned to universal use, which is why durability cannot be guaranteed for every eventuality.

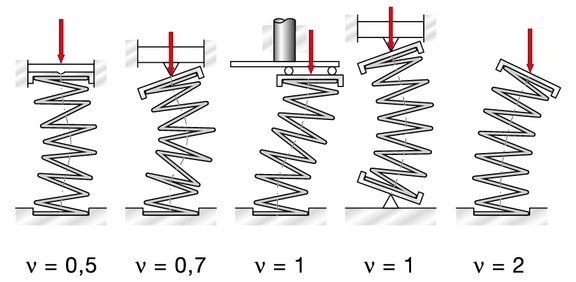

Buckling

Slim compression springs tend to bend and buckle. Safety against buckling depends on the ratio of length to diameter, the specific stress and the type of storage. The safety against buckling stated in the online shop and in the catalogue tables corresponds to the optimum case with a storage coefficient of v = 0.5. However, lopsided or unstable storage drastically increase the risk of buckling.

If there is a risk of buckling, the spring must be kept on a mandrel or in a sleeve and be adequately lubricated. The correct dimensions for the mandrel and sleeve are stated in our catalogue and in the online shop.

Dynamically highly stressed springs should have a high reserve or safety against buckling, because even slight bending considerably reduces the service life. In contrast to compression springs, tensions springs are always buckle-proof by their nature.

Our technical service will be happy to advise you with respect to difficult installation conditions.

Storage types in accordance with DIN 2089

compression spring storage type DIN 2089

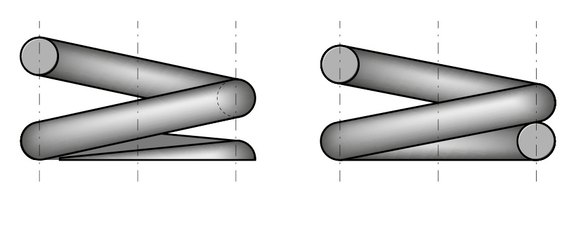

stacks of compression springs

stack of compression springs made of stainless steel and spring steel

They correspond to the spring dimensions from our shop, but are 1 m long and available in materials 1.1200 and 1.4310. With the stacks, at short notice you can realise interim solutions that you cannot find in our shop. Naturally, we also produce stacks with lengths of up to 40m to order.

Prior to use, the springs should be heat-treated:

material 1.1200: 220°C / 1 hour

Material 1.4310: 300°C / 1 hour

Stacks of springs are also ideally suited as buckle protection for hoses and cables.

The advantages of compression springs:

- Linear or progressive characteristic curves

- spring rate can also be influenced by material

- Pre-stressing the springs

- Durability guarantee on request

- Advice for difficult installation conditions

- Stacks of compression springs for short-term interim solutions