Cup Springs

Compact and powerful:

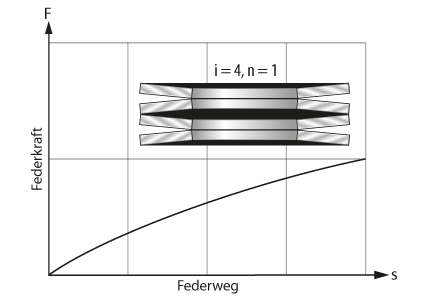

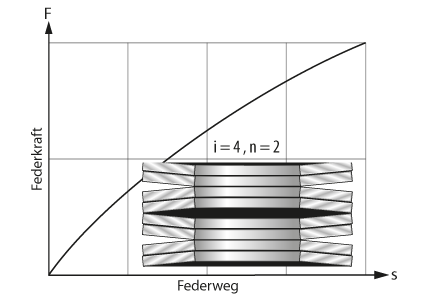

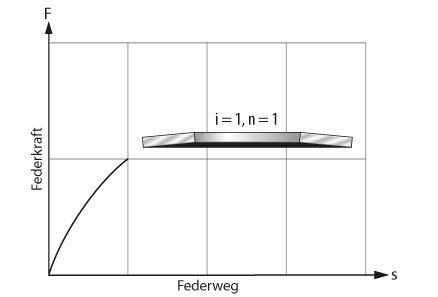

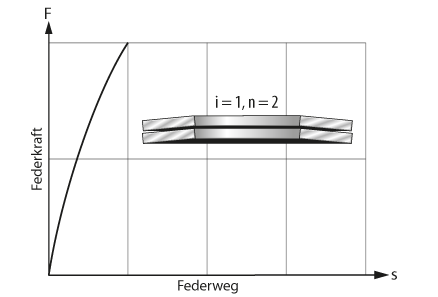

Two special properties characterise the cup springs: they are very compact and, at the same time, impress with their high strength. This means that they are predestined for use wherever installation space is limited but strong forces are still needed. Thanks to layering to form a cup spring stack, both the force and the spring deflection can be multiplied.

Cup springs are mainly used in the motor and electronics industry as well as in plant and mechanical engineering.

We manufacture cup springs that are corrosion- and temperature-resistance from the materials 1.4310 and 1.4568 – look for the size you want in our online shop or consult our expert team in the Pfullingen headquarters for advice.

Standardisation

DIN 2092 calculation formulae

DIN 2093 quality demands, dimensions

Manufacture of cup springs

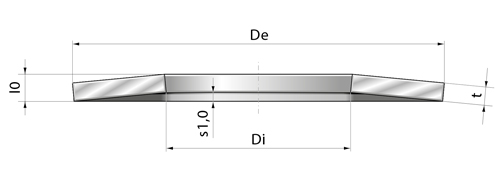

A distinction is made between three manufacturing groups, depending on the cup thickness (according to DIN 2093):

Group 1: t < 1.25 mm

Group 2: t 1.25 – 6 mm

Group 3: t > 6 mm

The advantages of cup springs:

- Small installation space, strong forces

- The possibility to combine individual cup springs is almost infinite, as a result of which the characteristic curve/stack length can be varied.