Die Springs and High-Performance Springs

We also put our stamp on this range of products:

designed for tool construction, these springs complement the range of cup springs. They are familiar under the names tool springs, retention clips or system springs. Since they are manufactured according to different values and dimensions, and in accordance with a draft ISO standard, greater tolerances apply to them than is usual for our standard spring range.

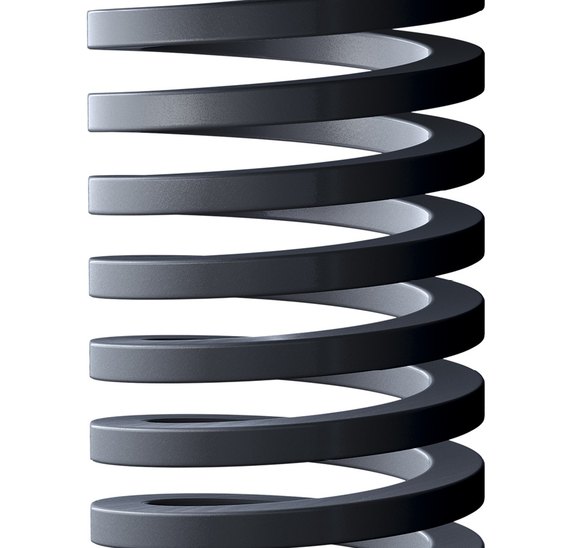

Die springs are cylindrical coil springs made of oval wire. The construction sizes have constant values with respect to installation space and spring forces. Wire diameter, number of coils, coil pitch and block length are not stated because these dimensions require a greater production compensation for technical reasons.

Please note:

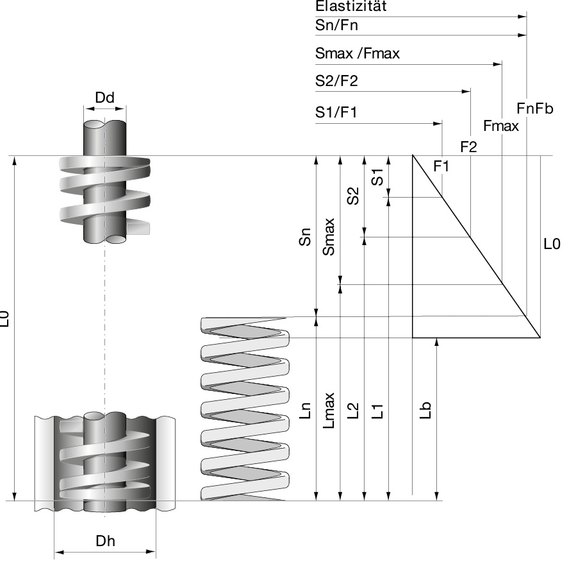

Stress and service life are defined as follows:

F1: Stress for long service life

F2: Stress for medium service life

Fmax: Maximum stress for short service life

Fc: Block stress

V: Select pre-stress in N as high as possible

S: Spring deflection in mm, select as low as possible

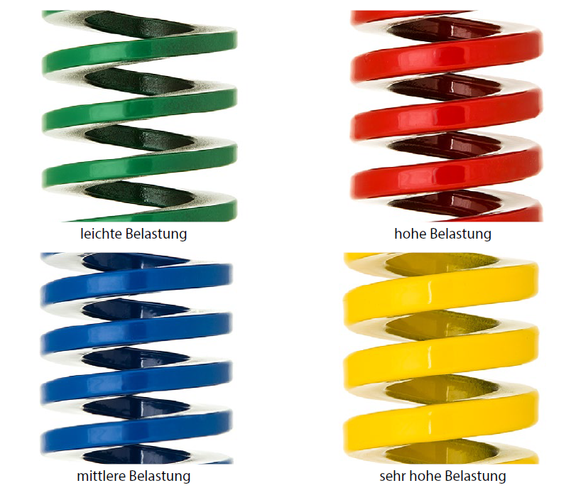

The springs are selected according to installation space and the 4 classes of stress:

Green – slight stress

Blue – medium stress

Red – heavy stress

Yellow – very heavy stress

The spring forces are stated in N.